The Four-sided tongue-and-groove machine is mainly used in conjunction with the polyurethane edge-sealing sandwich panel. The complete sealing of the end face of the core material is achieved through the cooperation of the folded edge and the blocking plate.

planking in which adjacent boards are joined by means of interlocking ridges and grooves down their sides.

Four-sided flanging/tongue-and-groove machine

The Four-sided tongue-and-groove machine is mainly used in conjunction with the Eps/Rock-wool/PU edge-sealing sandwich panel. The complete sealing of the end face of the core material is achieved through the cooperation of the folded edge and the blocking plate.

The Four-Sided Flanging Machine is an extremely efficient and effective machine designed for processing four-sided flange production in sandwich panels. It is an ideal tool for a wide range of industries such as engineering, automotive, construction and more. The machine is equipped with a tongue-and-groove-machine for sandwich panel production line and eps sandwich roof panel making. It is extremely efficient in producing smooth and uniform corrugation and flanges for sandwich panels.

This machine is equipped with a rapid flanging process. It can produce up to 600 meters of corrugated profile per minute. In addition, it is also equipped with a servo motor to precisely control the speed of the flange forming process. This ensures precision, accuracy and consistency in the output. Additionally, the machine operates in an extremely quiet and smooth operation, making sure not to disturb other operations running simultaneously in the production line.

This four-sided flanging machine is made of ultra-sturdy steel and is built to last. It includes the latest safety features for optimal safety and protection. The machine is also designed for easy operation and maintenance. It comes with two programmable controls for accurate, repeatable performance. The machine is fully automatic, so it is able to produce high-quality products multiple times. Additionally, it has adjustable settings to adjust the flanging process according to various production requirements.

The Four-Sided Flanging Machine is also easy to use. It includes a full-color monitor for capturing the different processes for monitoring each stage of the production. It also includes additional features such as an alarm system and fault detection system. This makes sure that the machine is in perfect working condition. In addition, the machine is CE certified, so it is a safe and reliable machine.

The Four-Sided Flanging Machine is a great tool for producing high-quality sandwich panels with a consistent and reliable output. It is a cost-effective and efficient machine that is suitable for a wide range of applications and uses. Its production rates and quality make it ideal for any production line. Plus, it is a safe and high performance machine that is sure to meet all of your production demands.

Device parameters:

1. Oil cylinder: 80mm, stroke 200mm, 8pcs;

2. Hydraulic station system pressure: <10Mpa; pump flow 20L/min;

3. Modules of the upper and lower synchronous gear racks: m=2;

4. roller synchronizing rack and pinion module: m=2;

5. Upper die material: Cr12; Lower die material: T10A;

6. L-shaped bending: height up to 150mm, actual width;

7. Roller diameter: C60mm; Support roller diameter: C60mm; .

8. PLC Delta brand

Features of processed tongue and groove panel products:

1. Concealed nail connection, no exposed screws on the surface.

2. The building wall is beautiful and smooth, the surface is smooth and flat, and the four-sided steel plate maintenance section replaces the decorative effect of the aluminum plate curtain wall.

3. The bending load resistance, the mechanical properties of the wall, and the dependence on the auxiliary steel structure are reduced.

4. There is no edge at the vertical docking point, and the surface is flat

5. The direct corner of the outer wall has no edge, which makes the corner part more delicate and straight.

6. It has good air tightness, water tightness and thermal insulation performance

Sandwich panels are a popular solution for obtaining insulation. The construction industry relies on good quality panels due to its several advantages. Countries, where there are extreme weather conditions require insulated panels to support the construction process. The Gulf countries, including Oman, are well known for the booming commercial and residential real estate market. The sandwich panels stand as a barrier against extreme weather conditions in the Gulf countries.

The confluence of durability and availability is the most common factor for completing an ongoing project. In this context, the sandwich panel will help to gleam through the ongoing construction project work. What is a sandwich panel? This question may brim on your mind. Sandwich panels are structural materials. It comprises a stiff core along with two face sheets. It has the top-notch structural ability, cost-effectiveness, and unparalleled durability. Here, we will unravel more advantages of sandwich panels.

Are you going to choose a material that possesses suitable thermal insulation properties? Sandwich panels in Oman can be the good one for you. Choosing a sandwich panel would be a clever task, whether it is a construction project or any other. The sandwich panel helps to lower energy costs. On top of that, it will decrease mold formation risk along with excess humidity.

Over the years, people are using sandwich panels due to their exceptional performance. When exposed to fire, they can withstand temperatures up to 1000 degrees centigrade. Most of the engineers and the building owners prefer sandwich panels for ensuring the safety of the employees and the equipment.

Sandwich structures are cost-effective as the core materials are not that expensive compared to other composite materials. On top of that, the durability of the fabric helps to cut off the maintenance cost.

There are solid laminates that are available on the market. Compared to the same, sandwich panels have a high strength-to-weight ratio. In turn, it can support required loads during transportation. It directly cuts off the transportation cost. Isn’t that great?

Color steel sandwich panel is an insulation composite maintenance board made of color coated steel plates or other panels and bottom plates and insulation core materials through adhesives. It is mainly used in anti-corrosion, pressure vessel manufacturing, power construction, petrochemical, and pharmaceutical industries . The sandwich panel is light in weight, about 10kg~14kg/square meter, equivalent to 1/30 of the brick wall; Thermal insulation, sealing performance good; convenient construction, flexible and fast installation, construction period can be shortened by more than 40%; Bright, beautiful appearance, no need for surface decoration; high strength, can be used as maintenance structure, load-bearing structure, bending and compression resistance, beams and columns are not required for general houses.

Our company's sandwich panel production line has absorbed the strengths of different manufacturers and combined with our own years of practice and research and development, we developed EPS sandwich panels machine and ordinary rock wool sandwich panel forming machine. On this basis, we developed an improved rock wool & EPS integrated sandwich panel forming machine. , Z lock sandwich panel forming machine, PU sandwich panel forming machine, and related supporting equipment.

|

Glue pump 1 set, supply the glue in proportion The compound machine chooses K-9 glue metering pump, with low speed and high measuring accuracy. The glue output is between 0.1-2.0kg/min, controlled by double motor and double frequency converter, and the four glue pumps are matched with black and white glue respectively, which make the glue usage more reasonable and more economical. |

|

|

3 sets of glue homogenizer, will fully mixed with the production glue and then applied on the steel plate, Glue homogenizer plate is pneumatic lift, more convenient and time - saving |

|

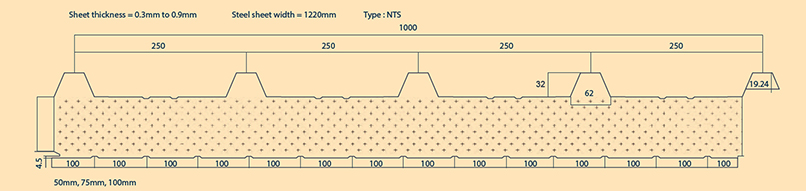

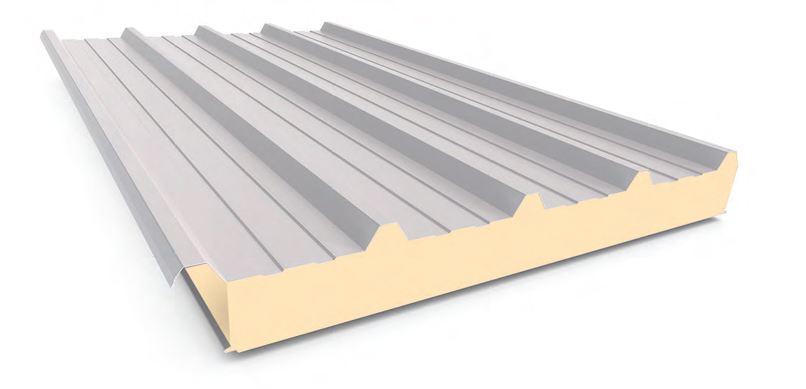

Roof panel with PIR (polyisocyanurate) and PU (polyurethane core). High surface profile.

Application:

Suitable for roofs of industrial buildings: production halls, storage buildings, commercial halls, shopping centres, farm facilities. Steel sheet lining with anticorrosive protection depending on the intended use.

Roof panel with PIR (polyisocyanurate) and PU (polyurethane core). High surface profile.

Application:

Suitable for roofs of industrial buildings: production halls, storage buildings, commercial halls, shopping centres, farm facilities. Steel sheet lining with anticorrosive protection depending on the intended use.

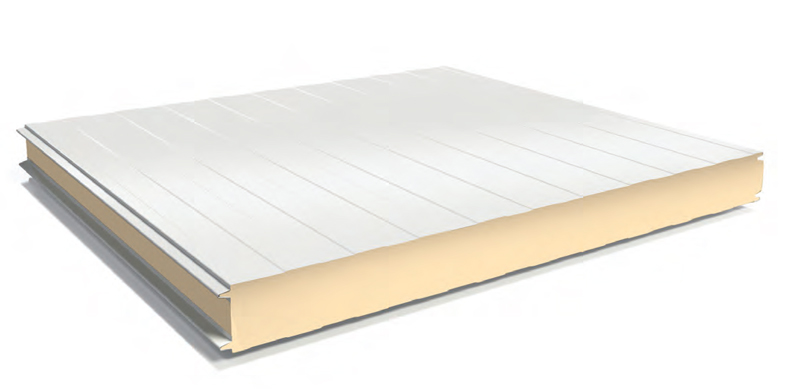

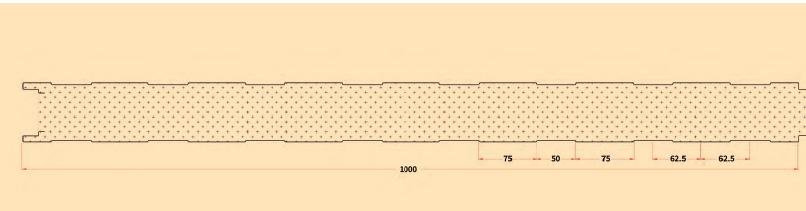

Low Ribbed Wall Sandwich panel with PIR (polyisocyanurate)and PU (polyurethane core).

Application:

Suitable for building external and internal walls of industrial buildings: production halls, storage buildings, commercial halls, shopping centres, farm facilities. Vertical or horizontal installation. Steel sheet lining with anticorrosive protection depending on the intended use.

The Four-Sided Flanging Machine is an extremely efficient and effective machine designed for processing four-sided flange production in sandwich panels. It is an ideal tool for a wide range of industries such as engineering, automotive, construction and more. The machine is equipped with a tongue-and-groove-machine for sandwich panel production line and eps sandwich roof panel making. It is extremely efficient in producing smooth and uniform corrugation and flanges for sandwich panels.

This machine is equipped with a rapid flanging process. It can produce up to 600 meters of corrugated profile per minute. In addition, it is also equipped with a servo motor to precisely control the speed of the flange forming process. This ensures precision, accuracy and consistency in the output. Additionally, the machine operates in an extremely quiet and smooth operation, making sure not to disturb other operations running simultaneously in the production line.

This four-sided flanging machine is made of ultra-sturdy steel and is built to last. It includes the latest safety features for optimal safety and protection. The machine is also designed for easy operation and maintenance. It comes with two programmable controls for accurate, repeatable performance. The machine is fully automatic, so it is able to produce high-quality products multiple times. Additionally, it has adjustable settings to adjust the flanging process according to various production requirements.

The Four-Sided Flanging Machine is also easy to use. It includes a full-color monitor for capturing the different processes for monitoring each stage of the production. It also includes additional features such as an alarm system and fault detection system. This makes sure that the machine is in perfect working condition. In addition, the machine is CE certified, so it is a safe and reliable machine.

The Four-Sided Flanging Machine is a great tool for producing high-quality sandwich panels with a consistent and reliable output. It is a cost-effective and efficient machine that is suitable for a wide range of applications and uses. Its production rates and quality make it ideal for any production line. Plus, it is a safe and high performance machine that is sure to meet all of your production demands.

Keywords: sandwich panel making machine